It is made in a similar fashion at a metal mill attached to the roof in the same way and installation costs are about the same.

Metal roof covering with its ribs down is called.

The means of attachment of one structural member to another.

Metal roof tiles are typically made of.

One of the best ways to cut down on metal roofing problems is to buy the materials from a reputable company that thoroughly tests its products and stands behind them with warranties.

Crushed stone or gravel ballast on a built up roof.

Structural metal roofing products are usually thicker than architectural products and are.

The key difference is in the appearance.

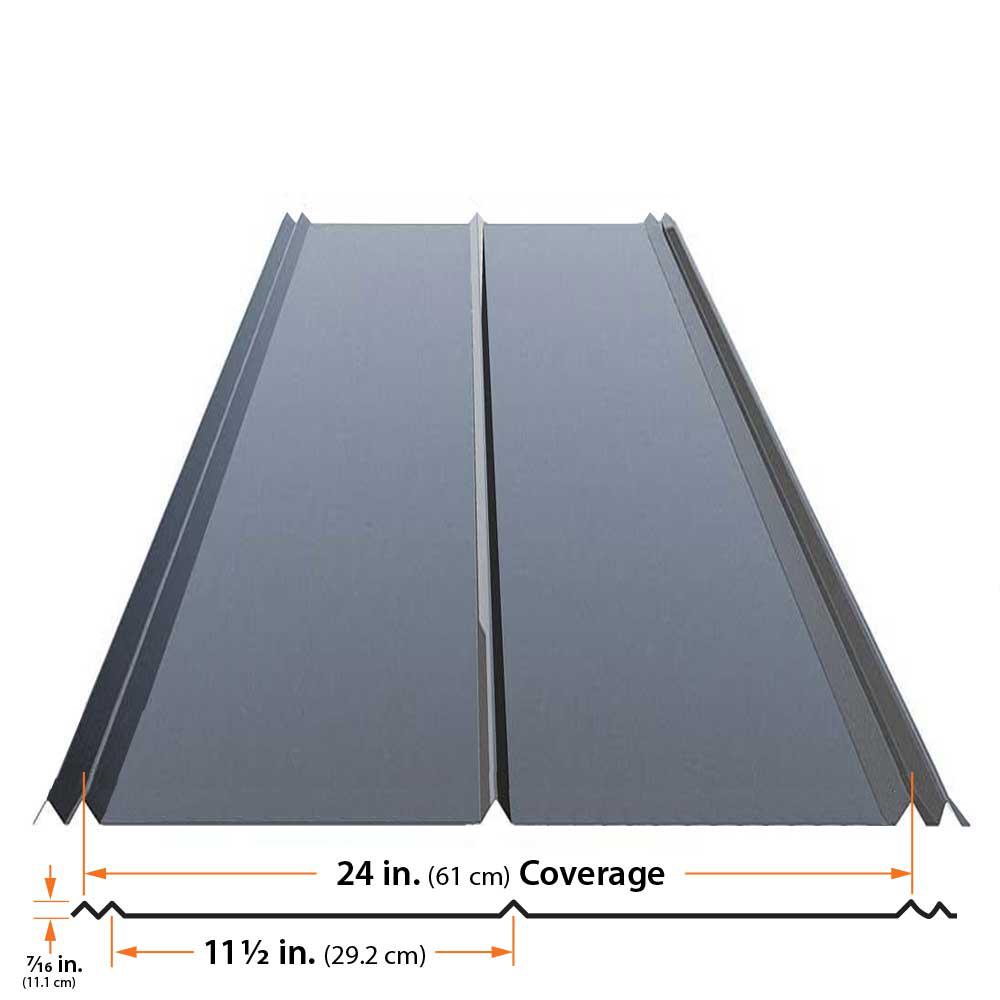

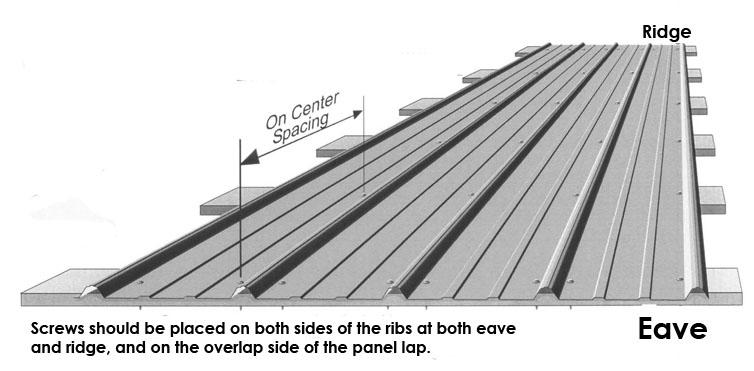

The ribs standing seams are usually between 12 and 24 inches apart depending on the length of the panel and aesthetics of the structure.

In some instances they are also steel lengths measuring about an inch or so wide that have an elevated middle where one screws the metal roofing into.

Protects the roof from sunlight.

Ribbed metal roofing is in the same family as corrugated metal roofing.

Over spanned rafters lack of collar ties.

The exterior metal roof and wall paneling of a metal building system.

Name three things that would cause rafter spread.

Batten or purlins can be 1 x2 x4 wood strips nailed to the roof or rafters upon which the roofing is attached.

A hold down clip used with a wall or roof panel system to connect the panel to the supporting structure without exposing the fasteners on the exterior surface.

A metal roof covering with the ribs down is called.

A standing seam metal roof system is a series of panels that are locked together at the seams or seamed mechanically.

Which one is correct.

A flashing along the peak of the roof is called the flashing.

Also referred to as purlins see purlin or purloin.

These products are called architectural metal roofing.

Most metal roofing products are designed to be installed over a supporting roof deck which bears the structural loads and transfers them down through the walls to the building foundation and then to the soil.